Factories tied to the Ram and Jeep brands were suddenly brought to a halt this spring. Stellantis, the automaker behind those iconic names, paused work at five major North American plants. According to Reuters and Fortune, the stoppage was blamed on sluggish demand and newly imposed U.S. auto tariffs, which immediately triggered about 900 layoffs in American facilities. The head of the United Auto Workers, Shawn Fain, called the move “a completely unnecessary choice.” Wall Street took notice, quickly knocking down Stellantis’ stock price. With jobs and vehicles in limbo, many wonder if this is just the beginning of deeper trouble.

Swift Layoffs Highlight Tariffs’ Real-World Effects

Nearly 900 workers across the U.S. were sent home with layoff notices as Stellantis responded to President Trump’s new 25 percent tariffs. CNBC reports that these cuts hit at least five facilities that are making or supporting Ram and Jeep models. The fallout extended into Canada, where the Windsor Assembly plant idled about 4,500 staff. Although not all jobs are directly linked to Ram and Jeep, whole communities feel the impact of the shutdown. Local leaders are warning that the economic strain will only deepen if these reductions persist.

Detroit’s Auto Heritage Faces Modern Pressures

Detroit has long been the heart of American auto manufacturing, with factories like Warren Truck and Jefferson North supporting the Ram and Jeep brands. Stellantis, which owns these brands today, has weathered plenty of crises, from government bailouts to international mergers. Still, experts say this year’s multi-plant freeze is unlike anything seen in recent memory. TFLcar notes that Jeep sales fell 9 percent year-over-year, with the Grand Cherokee and Wrangler among the most brutal hits. Both workers and fans ask if legacy alone is enough to weather these new challenges.

Price of Trade Wars Hits Assembly Lines

Automakers were scrambling mere days after Washington revealed steep new tariffs on imported cars and auto components. Dentons notes that the 25 percent levy caused costs to spike overnight for parts crossing borders. Stellantis quickly reduced production at its plant in Toluca, Mexico, and at Windsor in Canada, with both sites sitting idle for weeks. This had immediate ripple effects; suppliers hustled to rewrite contracts as whole supply lines slowed, sending fresh waves of uncertainty through the industry.

Five Factories Paused Amid Mounting Challenges

In early April, Stellantis confirmed what workers and analysts feared: production was frozen at five North American plants directly tied to Ram and Jeep. Reuters and Dealership Guy report that key stamping and transmission facilities in Michigan and Indiana fell silent, with major assembly sites in Windsor and Toluca also shut down. Ram 1500s and Jeep Grand Cherokees piled up at dealerships while company brass pointed to tariff struggles and softening consumer demand for the shutdowns.

Midwest Jobs and Families in the Crosshairs

Communities in Michigan and Indiana were among the first to feel the economic sting from these plant closures. Detroit’s Mack and Jefferson North plants, essential for local employment, idled hundreds of workers. Up in Kokomo, Indiana, layoffs hit the transmission and casting plants supplying both Ram and Jeep. Reuters shared that local officials have been pleading with Stellantis and federal authorities to resolve their standoff, knowing that every day of uncertainty hurts everything from diners to daycare centers.

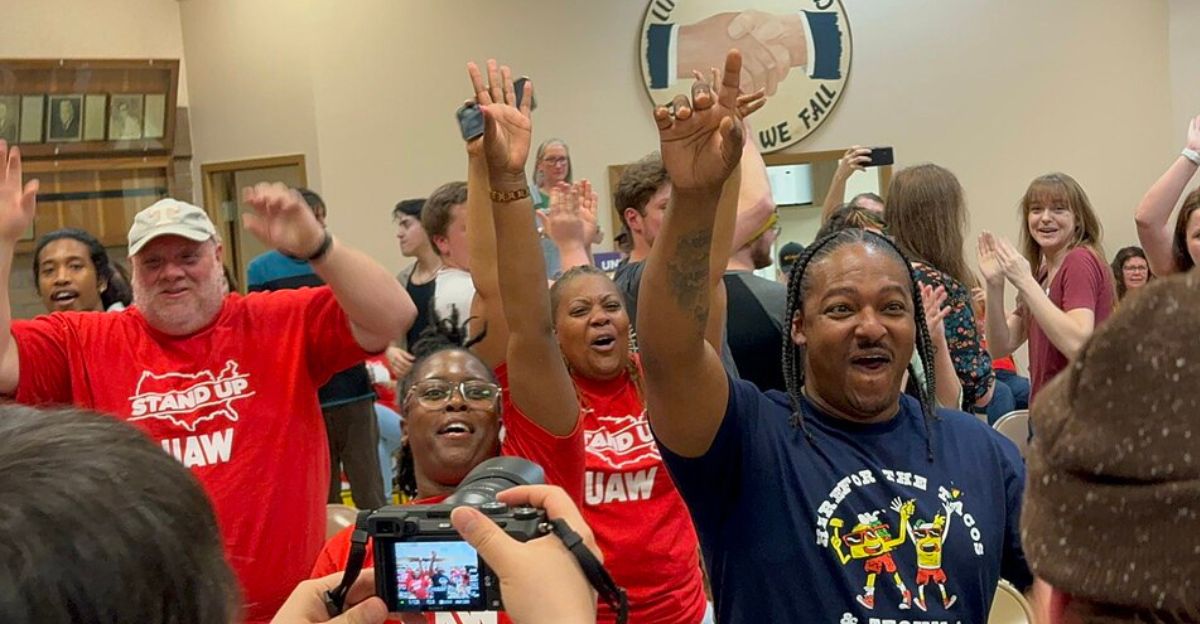

Laid-Off Workers Voice Fears for the Future

The real-life impact goes well beyond numbers. “These layoffs are a completely unnecessary choice,” United Auto Workers president Shawn Fain told Reuters. North of the border, union leaders in Canada blamed the tariffs for making a bad situation worse and criticized Stellantis for backing away from long-standing promises to the region. Social media filled with images of unused parking lots and silent assembly lines. Speaking to local news, a Kokomo worker summed up the mood: “Our lives are on hold.”

Rivals Rethink Production, Brace for More Changes

Major automakers are scrambling to adjust. Ford and GM, facing the same costly tariffs and slumping sales, have begun shifting truck and SUV assembly back to the U.S. where possible, though Car and Driver notes this takes time and investment. BMW and Toyota said they’ll cover the added costs, at least for now, but have warned consumers that sticker prices will almost certainly climb soon. In this chaotic environment, Ram and Jeep dealers have sometimes been forced to clear out inventory by offering their deepest discounts in years, according to TFLcar.

Falling Sales and Soaring Prices Raise Alarm

It’s becoming clear that the whole market is reeling. TTNews reports that total U.S. auto sales have slipped nearly 10 percent over the past year, with Ram and Jeep feeling even sharper drops. As buyers step back, dealers have been left with piles of unsold trucks and SUVs. Analysts quoted by TFLcar say that tariffs could add almost $9,000 to the price of some imported vehicles. In this market, that’s enough to make many customers postpone or cancel big purchases.

Ripple Effects Hammer Small Parts Suppliers

The pain extends well beyond big assembly plants. According to Bloomberg, smaller companies that supply parts to Ram and Jeep factories are being squeezed hard, many have reduced hours or furloughed staff as orders dry up. Cities like Detroit, Windsor, and Toluca depend on these suppliers for jobs and economic momentum. Some in the industry are warning that a wave of permanent shutdowns at these smaller firms could soon follow if the current freeze drags on.

U.S. Auto Dealers Run Out of Options

Dealers are now in a tough spot, facing inventory build-ups and uncertain timelines for production to ramp up again. Internal company memos cited by Dealership Guy reflect a growing anxiety: managers warn that today’s “supply cushion” could run out quickly if factory shutdowns persist. Some dealership teams are seeing fewer customers, while others say the buyers who show up negotiate harder than ever.

Leadership Shake-Up and Changed Launch Plans

Stellantis didn’t idle only plants. Facing pressure, the company quickly undertook executive shake-ups and delayed several new vehicle launches. Torquenews highlights that the Ramcharger hybrid and all-electric Ram 1500 REV plans have been pushed back. A spokesperson said Stellantis is reviewing its strategy and expects to eventually offer a broader range of powertrain options that better match shifting consumer tastes.

Stellantis Hopes Hybrid Launches Spark Recovery

Despite all the factory pauses and layoffs, Stellantis says it’s committed to the U.S. market. The company has told dealers that new models—including an updated Ram 1500 and a fresh take on the Jeep Cherokee—will begin rolling out late this year, assuming things stabilize. Stellantis is betting big that upcoming hybrid and electric vehicles can help lure Americans back into showrooms. It’s a high-stakes gamble, but doing nothing isn’t an option in this market.

Industry Uncertainty Sets the Stage for 2026

Auto industry experts aren’t sugarcoating the situation, most say 2025 is proving far more challenging than expected. Stellantis’ share price hit about 9 percent after news of the plant freeze, and broader worries remain about whether other automakers might have to follow suit. The real impact of these tariffs is still evolving, with some analysts warning that supply disruptions and price hikes could ripple for months. Most agree: nobody can count on a quick return to normal.

What’s Next for American Auto Workers?

Hundreds of families still await answers as core models like the Ram 1500 and Jeep Grand Cherokee sit in limbo. With major plants on pause, suppliers scaling back, and political fights over trade policy still unresolved, the future is anything but clear. Will Stellantis double down on investing in U.S. jobs or pull back even further? As buyers eye electric models and global supply chains shift, the next moves from automakers and officials may decide what’s left of America’s auto industry tomorrow.