In May, a startling stat exploded across social media: a truly 100% American-made car would cost around $400,000. TikTokers raged, Reddit threads spun theories, and politicians either cheered or scoffed.

But here’s the deeper truth, this isn’t about cars. It’s about how everything we use, from insulin to iPhones, is embedded in global supply webs. Cars just happen to be the most visible and complex example.

Rebuilding every link domestically means multiplying costs across the board. If that $400,000 sticker shocks you, ask yourself: what happens when the same logic is applied to food, housing, tech, and medicine? Let’s unpack the ripple effect.

Global Supply Chains Are the Real Factory Floor

A product isn’t built in one place, it’s born from a thousand locations. Today’s average vehicle uses over 20,000 parts sourced globally, with just 40–50% actually made in America.

Coffee beans from Colombia are roasted in Europe, packaged in Chinese plastics, and shipped via Korean vessels. This is the norm, not the exception. Every major industry, from smartphones to insulin; relies on a patchwork of specialized global contributors.

“Made in America” isn’t just expensive; it’s structurally impossible without rebuilding entire ecosystems. The myth of the local factory ignores a brutal truth: the world no longer builds things in one place.

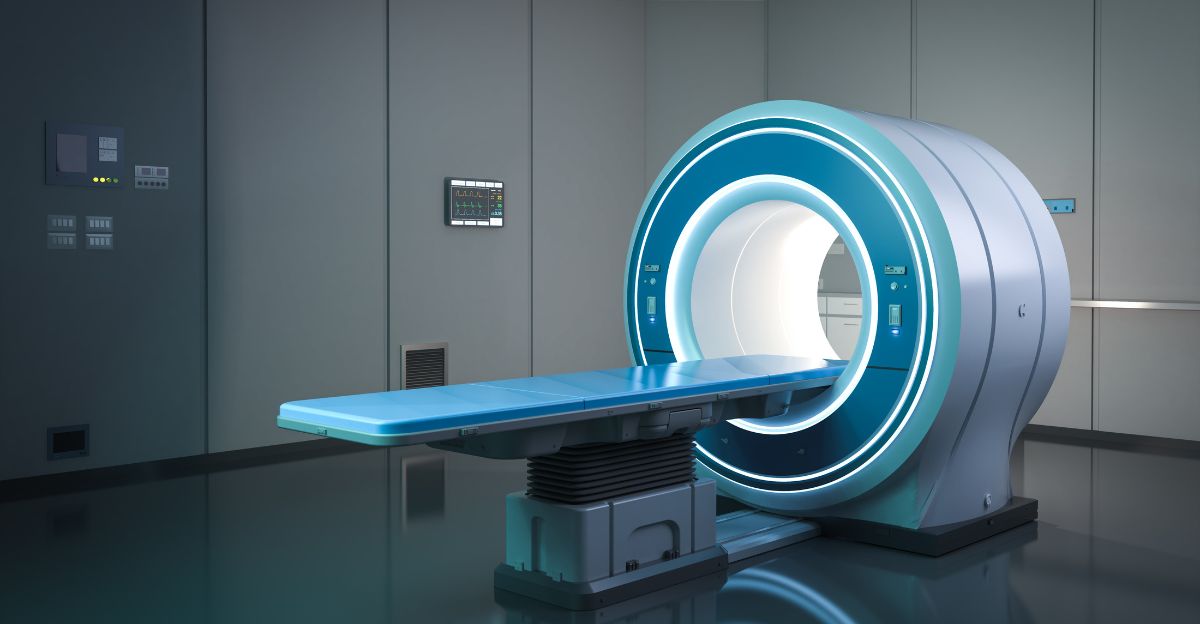

Healthcare Would Crack Under National Pressure

In 2025, a family of four already spends over $35,000 annually on healthcare. But most medical equipment, MRIs, ventilators, even basic surgical tools, depends on global parts. The superconducting magnets in MRIs? Rare earths from China. The electronics inside insulin pumps? Circuit boards from Taiwan. And generic drugs? Often 90% of their ingredients are made in India or China.

Force all of this to be American-made, and costs double or triple instantly. It’s not just price hikes, it’s capacity collapse. Domestic pharma can’t suddenly replace decades of offshored production. “Made here” might sound patriotic, but for healthcare, it’s economically reckless.

Schools Can’t Afford to Go It Alone

Education already comes with steep bills, $63,000 a year for private college, with K–12 increasingly dependent on tech. Laptops, smart boards, cloud servers, all rely on global parts and software talent. Semiconductors alone require clean rooms and ultrapure chemicals found in Asia, not Alabama.

Even if America wanted to onshore it all, fabrication plants take 3–5 years to build and billions in public funding. Meanwhile, student needs don’t pause. If you force domestic content rules here, schools will choose between cutting digital tools or bleeding their budgets. Either way, it’s the kids who lose, left behind in a world racing forward.

Your Grocery Bill Would Double Overnight

Food is global, even when it looks local. That “Made in Idaho” potato was fertilized with potash primarily from Canada and Russia, harvested with Japanese engines, and sprayed with German-made chemicals. Your cereal box? Likely printed on Chinese cardboard, using Brazilian pulp and American corn.

Break any one link, and the whole chain seizes. Requiring every element of food production to be American-made would skyrocket costs and strain supply. With Americans already spending over $6,00 annually on groceries, basic nutrition would shift from commodity to luxury.

For millions already living paycheck to paycheck, that’s not just inconvenient, it’s destabilizing. Domestic-only agriculture risks triggering a silent food crisis few politicians are prepared to manage.

Housing Will Become a Millionaire’s Market

Housing costs are already untenable in most U.S. cities. Add domestic-only requirements, and you’ll price out even modest homes. Why? Electrical systems need copper from Chile. Insulated glass panels require European coatings. Smart thermostats rely on chips from Taiwan. Construction isn’t just hammer and nails, it’s logistics, chemistry, and tech.

Without global suppliers, builders must substitute more expensive or lower-quality components, if they can find them at all. Homes could cost 2–3 times more, choking supply and deepening the housing crisis. In effect, policies claiming to protect the American dream would ensure it stays out of reach for most.

Tech Innovation Dies in a National Vacuum

The smartphone in your pocket is built from materials sourced across 60 countries, a symbol of the intricate global web behind modern technology. Domestic content rules would expose a core truth: American innovation thrives on international collaboration. Ultra-pure silicon comes from a handful of specialized global plants. Rare earth elements, vital for batteries and screens, are mostly controlled by China.

Even software depends on global talent. U.S. tech firms succeed not in spite of globalization, but because of it. Forcing everything to be “Made in America” would break these optimized supply chains, raising costs and slowing innovation. The result? Weakened U.S. leadership in a world where speed and scale define success.

The Emotional Toll: Cognitive Dissonance by Design

Americans pride themselves on choice and affordability. But economic nationalism flips that script. Imagine standing in Target, facing a $40 toaster “Made in USA” next to a $12 Chinese one, but being legally barred from buying the cheaper option. That’s not patriotism. That’s resentment.

Studies on trade restriction stress show increased consumer anxiety and distrust. When prices rise without perceived improvements, people rebel. It’s not just economics, it’s psychological. If everything becomes harder to afford because of a policy few fully understand, faith in institutions erodes. The average shopper doesn’t want to be a martyr for manufacturing strategy. They just want eggs that don’t cost $9.

History Repeats—And It Doesn’t End Well

America has tried this before. The 1930 Smoot-Hawley Tariff backfired spectacularly, deepening the Great Depression. In the 1980s, Brazil’s attempt to isolate its computer industry led to outdated tech at five times global prices. Even modest “Buy American” rules in cars led to higher prices and fewer choices. When governments force artificial self-sufficiency, consumers lose, and innovation stalls.

Protectionism may help a few industries in the short term, but it creates national blind spots and brittle economies. Every past example shows the same outcome: self-imposed economic gravity that slows everything down. Nostalgia can’t outsmart economic physics.

America Doesn’t Need Isolation—It Needs Intelligence

The $400,000 car isn’t about cars. It’s about what happens when we mistake slogans for strategy. Total economic independence sounds appealing, until you realize it means abandoning affordability, innovation, and global competitiveness. The U.S. can be a manufacturing powerhouse without walling itself off. The solution isn’t purity, it’s balance. Strategic reshoring makes sense for critical sectors like defense, energy, and biotech.

But blanket “Made in America” mandates ignore scale, cost, and the very networked nature of the modern world. Competing globally doesn’t mean surrendering sovereignty. It means choosing partnerships wisely and building resilience through smart, not stubborn, policy. Let’s choose strategic strength, not economic self-sabotage.

Discover more trending stories and Follow us to keep inspiration flowing to your feed!

Craving more home and lifestyle inspiration? Hit Follow to keep the creativity flowing, and let us know your thoughts in the comments below!