This month, food safety alerts have hit a new high, with emergency recalls affecting millions of American families. On July 11, 2025, Danone U.S. recalled all YoCrunch yogurt products following consumer reports of sharp plastic fragments in toppings.

The clear plastic fragments, ranging from 7 to 25 millimeters, pose serious choking and injury risks for consumers nationwide. Federal health agencies have revealed that this is one of the most extensive yogurt recalls in recent memory, including every flavor and size currently available in stores.

Many have been left shaken by this recall. Daniel Wagner, a food safety attorney, spoke to Natural News, saying: “Companies like Danone must invest in rigorous testing. Consumers aren’t just worried about choking hazards—they’re right to fear what we can’t see.” But that’s not all.

The Deep Brand Frozen Sprouted Beans Recall

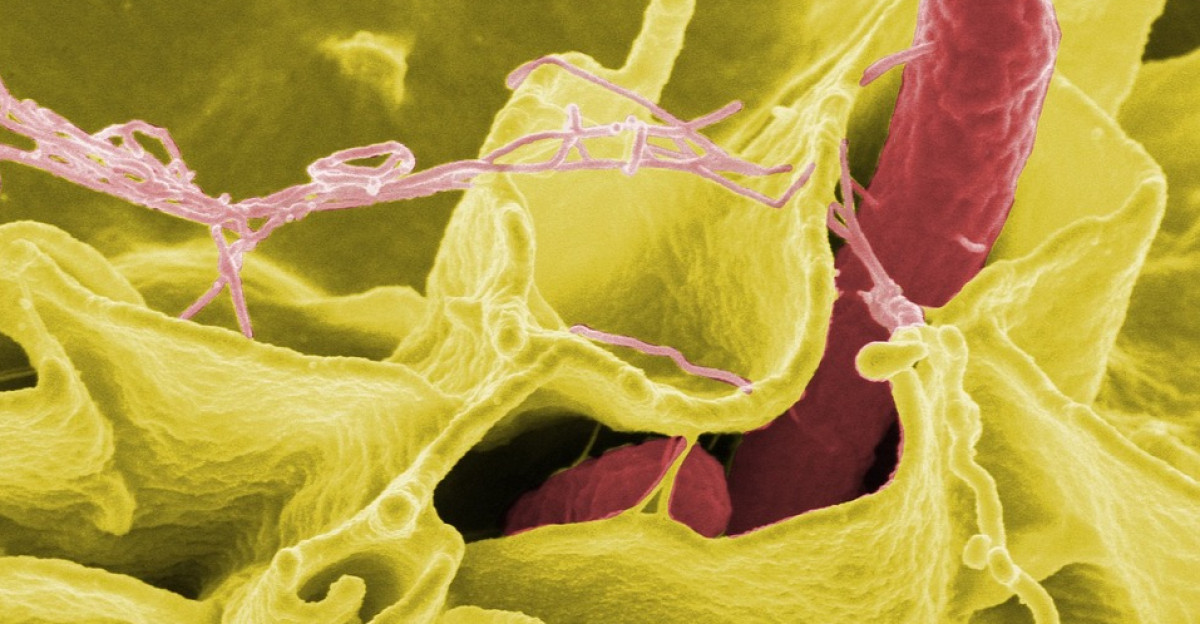

Meanwhile, multi-state health also detected a dangerous Salmonella outbreak across 10 states, affecting 11 individuals, four of whom required hospitalization. The Centers for Disease Control and Prevention confirmed the outbreak strain matches bacterial contamination found in CHETAK LLC GROUP’s Deep brand frozen sprouted beans through advanced genetic sequencing technology.

State health departments from Connecticut to Washington have found illness cases dating back to October 2024, showing that the contamination possibly went unnoticed for months. The FDA discovered the issue during routine testing, leading to an urgent product recall on July 16, 2025.

The Golden Raisin Recall

In July 2025, a major golden raisin recall was issued after routine New York State Department of Agriculture testing discovered undeclared sulfites in products distributed by multiple companies, including Nirwana Foods.

The presence of undeclared sulfites posed a serious risk to individuals with sulfite allergies, potentially triggering severe or life-threatening reactions.

Supply Chain

America’s complex food distribution network has allowed contaminated products to reach store shelves across the country before being flagged. YoCrunch yogurt has made its way into major retailers like Walmart, Target, and Dollar General, affecting shoppers nationwide.

The frozen sprouted beans were sold through Indian grocery stores and specialty markets, putting diverse communities at risk. Meanwhile, golden raisins from brands like Nirwana Foods were distributed to Maharaja Super Markets and Villager Farmers Markets in the New York and New Jersey areas, further widening the reach of potential exposure. But how did this happen?

Manufacturing Vulnerabilities

Industrial food production systems have shown major flaws in quality control during the busy summer distribution season. In Danone’s case, the plastic contamination came from faulty dome topper manufacturing, where safety checks failed to catch sharp fragments before packaging.

CHETAK LLC GROUP has paused all frozen sprouted bean production as federal teams investigate multiple facilities across six states.

Meanwhile, routine testing by New York’s Department of Agriculture found undeclared sulfites in golden raisins, pointing to widespread labeling issues among dried fruit manufacturers.

Federal Response

In July 2025, the Food and Drug Administration and Centers for Disease Control and Prevention launched joint emergency response efforts to tackle multiple contamination incidents at once. Federal agencies deployed advanced whole-genome sequencing technology to confirm the genetic match between Salmonella found in sprouted beans and illness cases reported across state boundaries.

The FDA partnered with Danone U.S. to carry out the widespread recall of YoCrunch yogurt, working closely with retailers to pull affected products from thousands of stores across the country. Consumer safety alerts reached the public through multiple communication channels including official FDA websites, CDC outbreak investigation updates, and direct retailer notifications.

Regional Impact

State health departments mobilized extensive surveillance networks to monitor illness trends and trace product distribution in affected areas. Massachusetts confirmed two Salmonella cases linked to the sprouted bean outbreak, with additional cases reported in Florida, Illinois, New Jersey, Pennsylvania, Virginia, and Washington.

New York state agriculture inspectors discovered sulfite contamination through routine sampling programs, which triggered recalls across multiple golden raisin distributors operating in northeastern markets. Regional grocery chains like Albertsons and Kroger quickly removed these products from their shelves, affecting inventory management and consumer shopping patterns across multiple states. However, this situation also had a major impact on consumers.

Consumer Stories

any American families found contaminated food in their homes weeks after purchase, sparking growing concerns about the safety of everyday groceries. In response to reports of sharp plastic in yogurt, Danone stated, “We take every consumer experience seriously and are issuing this voluntary recall in line with Danone’s commitment to product quality and consumer safety.”

Parents reported finding sharp plastic pieces in their children’s yogurt containers, while families with sulfite allergies faced potentially life-threatening reactions from mislabeled raisin products.

Consumer advocacy groups have emphasized that grocery stores failed to provide adequate recall notification systems, leaving families to learn about contaminated products through media reports rather than direct retailer communication.

Industry Analysis

Food safety experts warn that simultaneous multi-product recalls point to deeper structural problems in America’s industrial food production and distribution systems. Recent data indicates that 2024 saw a 41% increase in food recalls compared to previous years, with hospitalizations more than doubling from 230 in 2023 to 487 in 2024.

Industry experts point out that plastic contamination, bacterial outbreaks, and allergen mislabeling highlight three separate types of manufacturing failures that can occur simultaneously across different food categories. Supply chain vulnerability assessments also show that global food distribution networks create multiple exposure points where contamination can spread quickly across different areas before detection systems activate.

The recent recall crisis highlights the importance of improvements in food safety monitoring systems, but what can we expect to come from this?

Future Implications

These recalls could accelerate regulatory reforms and technological improvements in food safety monitoring systems as agencies prepare for increasing contamination risks. Federal agencies are implementing enhanced traceability requirements under the Food Safety Modernization Act, requiring manufacturers to keep better records for faster recall responses.

Industry executives have predicted that artificial intelligence and blockchain technologies could become standard tools for monitoring food safety throughout complex supply chains, potentially preventing contamination from reaching consumer markets. Will these technological advances prove sufficient to prevent future multi-product recall scenarios, or do fundamental changes in food production and distribution systems require more comprehensive regulatory intervention?